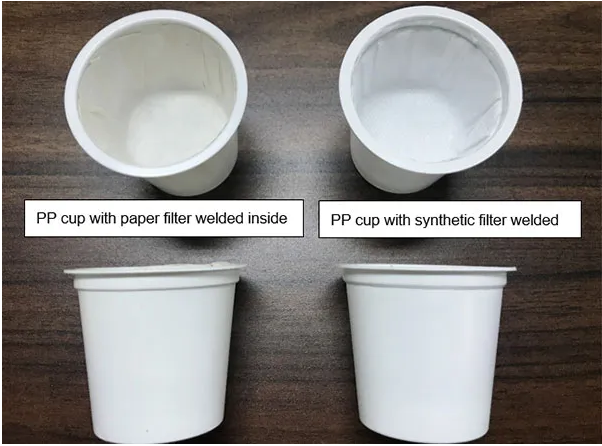

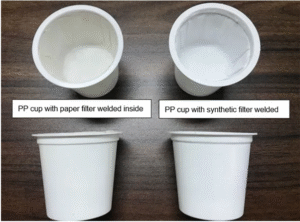

Our company provides one-stop service of Nespresso coffee capsule filling machine, K cup filling machine, coffee bag packaging equipment, coffee capsule packaging machine, plastic empty K cup, aluminum K cup, Nespresso empty cup, coffee powder packaging machine, coffee packaging machine, coffee bean packaging machine, small coffee packaging machine, Dolce Gusto filling packaging packaging machine, coffee bag filling machine, coffee capsule packaging machine, small coffee capsule filling machine, Nespresso cartoning machine, K cup capsule cartoning machine, coffee bean roasting machine, etc. You are welcome to purchase.