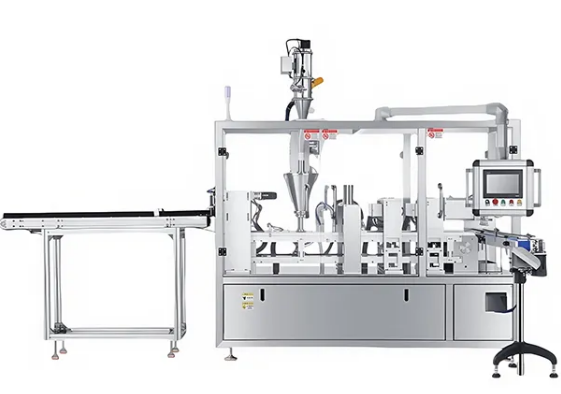

coffee capsules have become an indispensable part of the modern coffee industry. With the increase in consumer demand, how to improve production efficiency has become the main challenge facing manufacturers. As a key equipment in the coffee production line, the coffee capsule filling machine plays a vital role in improving production efficiency. So, how does a coffee capsule filling machine improve production efficiency? This article will analyze it from multiple aspects.

1. Automation and intelligence

One of the major advantages of coffee capsule filling machines is that they can realize a fully automated production process. Traditional manual filling or semi-automatic filling is not only time-consuming, but also prone to human errors, thereby reducing production efficiency. Modern coffee capsule filling machines are equipped with intelligent control systems that can accurately control each step of the operation process.

The automated process can not only greatly reduce manual intervention, but also increase production speed while ensuring quality. Through advanced sensors and control systems, the filling machine can automatically detect capsule status, filling volume, packaging status, etc., and make corresponding adjustments as needed. For example, when the capsule filling volume is insufficient, the system can immediately identify and automatically replenish it, thereby avoiding production interruptions and waste of resources.

The automated process can not only greatly reduce manual intervention, but also increase production speed while ensuring quality. Through advanced sensors and control systems, the filling machine can automatically detect capsule status, filling volume, packaging status, etc., and make corresponding adjustments as needed. For example, when the capsule filling volume is insufficient, the system can immediately identify and automatically replenish it, thereby avoiding production interruptions and waste of resources.

2. Improve filling accuracy

Improving production efficiency is not only about increasing production speed, but also about ensuring the filling accuracy of each capsule. Modern coffee capsule filling machines use precision filling devices that can accurately fill each capsule in a very short time.

As consumers’ requirements for coffee taste increase, filling accuracy is particularly important. By accurately controlling the weight of coffee powder filled each time, the coffee concentration and flavor of each capsule can be ensured to be consistent, thereby reducing rework or waste in the production process due to uneven taste. At the same time, the precision filling system can effectively avoid production failures caused by overfilling or leaking, thereby improving overall production efficiency.

3. Versatility and flexibility

Modern coffee capsule filling machines are not limited to single coffee capsule production. Many devices can be flexibly adjusted according to demand to adapt to different types of capsules and recipes to meet diverse market needs. Whether it is different flavors of coffee powder, different sizes of capsules, or different packaging methods, they can be achieved through simple adjustments.

This flexibility allows manufacturers to respond quickly to market changes and meet the needs of different consumers without having to reconfigure or stop production. It improves the comprehensive utilization rate of the production line and avoids the loss of production stoppage caused by production line adjustment, thereby further improving production efficiency.

4. Quick replacement and easy maintenance

For any production equipment, downtime for maintenance or adjustment of the production line will affect production efficiency. Modern coffee capsule filling machines are designed with great emphasis on quick replacement and easy maintenance. Some equipment adopts modular design, and production line operators can complete the replacement of accessories or adjustment of settings in a short time, thereby minimizing downtime.

In addition, with the continuous advancement of technology, many filling machines are also equipped with remote monitoring and diagnostic systems, and problems with the equipment can be discovered and handled in time through remote diagnosis. This remote technology enables maintenance personnel to obtain equipment status in the first time, avoiding long-term shutdown of the production line due to equipment failure, and further ensuring production efficiency.

5. Enhance the synergy of the production line

Coffee capsule filling machines are often not just isolated working units, they are usually part of the entire production line. By working in collaboration with other automated equipment, such as packaging machines, sealing machines, inspection machines, etc., an efficient production system can be formed.

For example, during the filling process, the filling machine can automatically send the filled capsules to the sealing machine, and then send them to the inspection machine for quality inspection after sealing, and finally the packaging machine completes the whole box packaging. This systematic operation process can greatly reduce manual intervention and bottlenecks in production, ensure efficient connection of each link, and improve overall production efficiency.

6. Data analysis and optimization

Modern coffee capsule filling machines are usually equipped with data acquisition and analysis systems, which can monitor various data in the production process in real time. These data include not only production speed, filling accuracy, equipment operation status, etc., but also efficiency indicators of each production link.

By analyzing these data, companies can find bottlenecks, potential problems or unreasonable operation processes in the production process, and then take targeted measures to optimize them. For example, if it is found that the production speed of a certain link is slow, it may be due to equipment failure or improper operation. The company can make timely adjustments to ensure that the overall production process remains efficient.

Conclusion

Improving production efficiency is an important goal of every coffee capsule manufacturer, and coffee capsule filling machines are the key to achieving this goal. Through automation, intelligence, precise filling technology, multifunctional flexibility and systematic production line synergy, coffee capsule filling machines can greatly improve production efficiency and reduce unnecessary costs and waste. For the coffee industry, choosing the right filling equipment can not only improve production efficiency, but also occupy a place in the fiercely competitive market.